Industrial Agitated Thin Film Dryer in India

An Industrial Agitated Thin Film Dryer In India (ATFD) is an industrial drying solution designed for drying high-viscosity liquids, slurries, pastes, and heat-sensitive materials efficiently. It is widely used in industries like pharmaceuticals, chemicals, food, and wastewater treatment.

SKTMPL Pvt. Ltd. is the leading Industrial Agitated thin film dryer manufacturer In India and supplies these distilleries to the widest range of industries. Our Agitated Thin Film Dryer In India has a fully integrated design and is based on successful process technology.

About AGITATED THIN FILM DRYER

Industrial Agitated thin film evaporator in India (ATFD) is used for continuous drying of heat-sensitive products under vacuum with total solvent recovery. ATFD provides high throughput by efficiently working under vacuum. ATFD uses indirect heating and drying in inert conditions which is effective for heat and oxygen sensitive products. An Agitated Thin Film Dryer (ATFD) also known as Thin Film Evaporator (TFE) are used to produce free flowing powder from slurry/solution type feed and widely implement in pharmaceutical, chemical & food industries. These are used in situations where the solutions cannot be handled by conventional dryers/evaporators.

Applications of agitated thin flim dryer

1. Pharmaceutical Industry: Drying API slurries, herbal extracts, and intermediates.

2. Chemical Industry: Drying polymers, resins, pigments, and dyes.

3. Food Industry: Drying malt extracts, proteins, and fruit/vegetable purees.

4. Wastewater Treatment: Recovering solids from effluents and sludges.

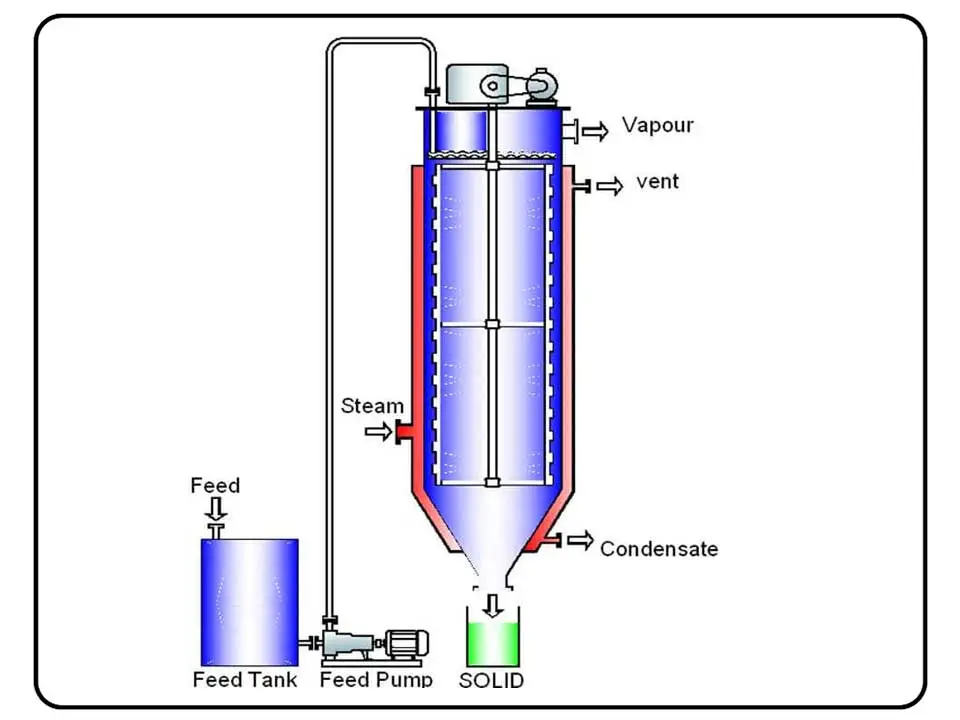

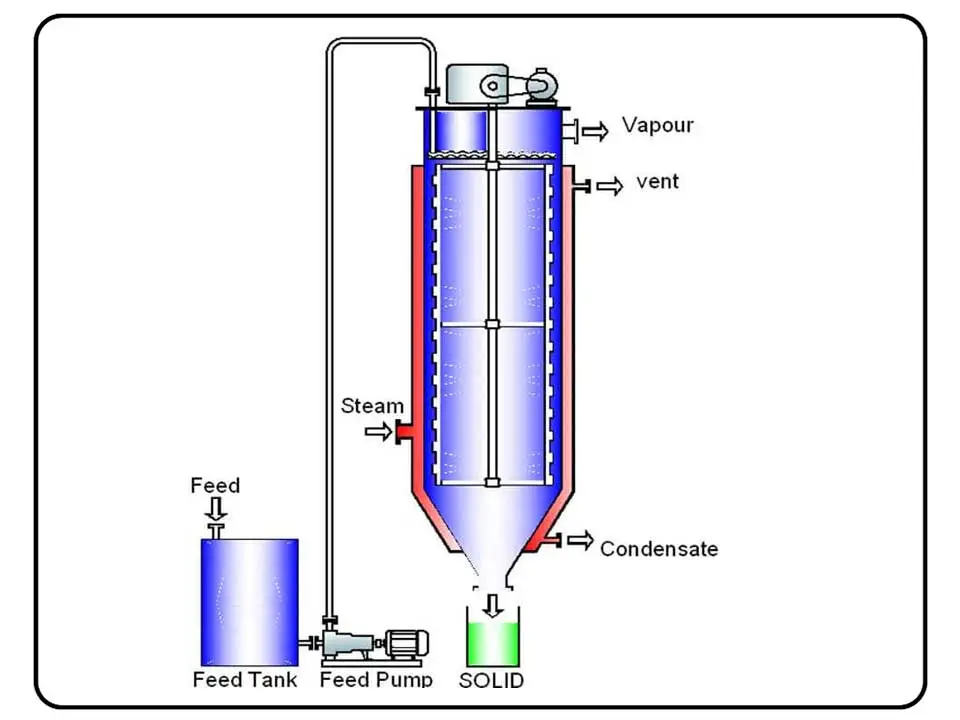

How Agitated Thin Film Dryer works

1. Feed Material: The wet feed (liquid, paste, or slurry) is introduced at the top of a vertical or horizontal cylindrical drying chamber.

2. Thin Film Formation: A rotating agitator with specially designed blades spreads the feed into a thin film on the heated surface.

3. Evaporation: Heat is applied to the cylindrical surface, causing rapid evaporation of moisture from the thin film.

4. Separation: The vapors are collected and condensed, while the dry product (powder, flakes, or solids) is discharged at the bottom.

Discover the Perfect Flim Dryer for Your Industry—Start Here!

FAQs

1. What is an Agitated Thin Film Dryer, and how does it work?

2. Who is the best Agitated Thin Film Dryer manufacturer in India?

3. What are the applications of an Agitated Thin Film Evaporator in India?

5. What are the advantages of using an Agitated Thin Film Dryer in India?

✅ High thermal efficiency

✅ Faster drying process

✅ Low maintenance and operational cost

✅ Suitable for heat-sensitive products

Important Keywords: Industrial Agitated thin film dryer supplier in India, Industrial Agitated thin film dryer manufacturer In India, Industrial Agitated thin film evaporator supplier in india, Industrial Agitated thin film dryer supplier for Pharmaceutical Industry, Industrial Agitated thin film dryer supplier system for Chemical Industry, Industrial Agitated thin film dryer supplier system for Food Industry, Industrial Agitated thin film dryer supplier system for Wastewater Treatment.

Related Searches: Rotary Dryer Services Provider In India | Spray Dryer Services Provider In India | Agitated Thin Film Dryer Services Provider In India | Spin Flash Dryer Services Provider In India | Fluid Bed Dryer Services Provider In India | Industrial Dryer System Supplier In Provider | Industrial Drum Dryer System Provider in India | Steam Tube Rotary Dryer In India