Industrial Rotary Dryer System Provider in India

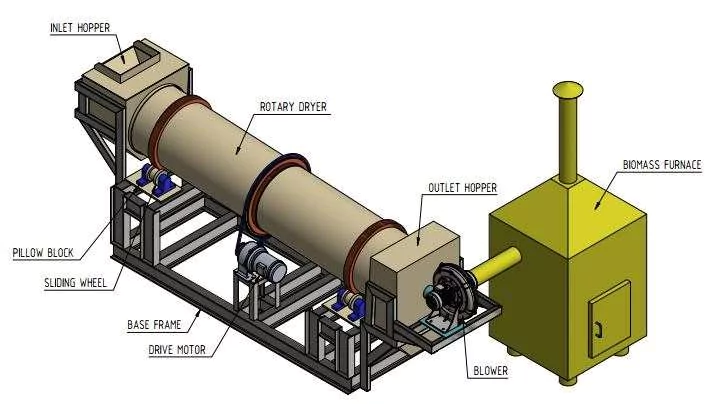

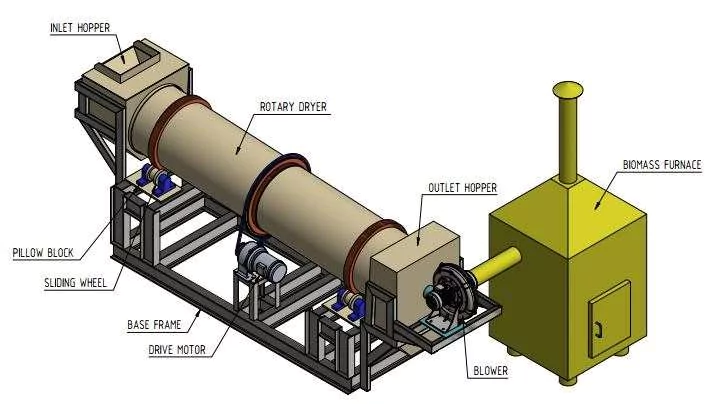

An Industrial rotary dryer is a type of industrial drying system used to reduce the moisture content of various materials. It is widely employed in industries such as mining, agriculture, chemical processing, and manufacturing.

SKTMPL Pvt. Ltd. is the leading Industrial Rotary Dryer System Provider in India and supplies these distilleries to the widest range of industries. Our Industrial Rotary Dryer System in India has a fully integrated design and is based on successful process technology.

About Rotary dryer

Industrial rotary drier machine is continues drying process & are widely used for drying Minerals, Chemical and other solid Material Or Removing Damp (moisture) from Material. It is also used of heating (roasting) material .We offer our clients rotary drier with fine and excellent grade, which is used in drying and heating of materials with excellent Results. And we design it according to requirement and usage of client

Use of Rotary Dryer in Industries

1. Braveries – DDGS (Dried Distillers Grain Solid)

2. Chemical Industries – Salts, Phosphates, Metal sludge, Soda Ash, Silica, Carbon Black.

3. Petrochemical Industries – Polymers, PVC, HDPE, PTA.

4. Mineral Industries – Clay, Coal, Fireclay, Limestone, Axonove, Sand, Slag.

Technical Specifications of a Rotary Dryer

1. Drum Structure: Typically made from carbon steel, stainless steel, or specialized alloys for heat and corrosion resistance.

2. Dimensions: Diameter: 0.5 to 4 meters (or more for large-scale units).

Length: 3 to 30 meters (can be customized based on application).

Performance Metrics

1. Thermal Efficiency: Depending on design and insulation.

2. Evaporation Rate: Dependent on heat input, material properties, and airflow.

3. Material Loss: Typically <5% with proper sealing and system design.

"Discover the Perfect Rotary Dryer for Your Industry—Start Here!"

Industrial Drum Dryer System Provider in India

Industrial Drum Dryer consists of a rotating drum, usually positioned horizontally, which is heated either by direct contact with hot air or by utilizing hot gases flowing through the drum. Wet or moist materials are fed into the inlet end of the drum and are continuously lifted and showered through the hot air or gas stream as the drum rotates. This process causes the moisture to evaporate, resulting in dried solids exiting from the other end of the drum.

Steam Tube Bundle Rotary Dryer

Unlike traditional Rotary Drum Dryers System Provider In India, which utilize a rotating drum or shell, this advanced design incorporates a stationary shell with internal steam tube bundle. The concept of a steam tube rotary drier revolves around the principle of indirect heating. Steam is introduced into the tubes, which are positioned inside the stationary shell. The material to be dried is fed into the shell, and as it comes into contact with these rotating hot steam tubes, the heat is transferred to the material, causing moisture to evaporate. The feed material is continuously lifted, showered with the help of shovels provided on tube bundle.

The absence of a rotating shell eliminates the need for complicated mechanical components, such as tires, trunnion rollers, and drive systems. This simplification results in a more compact and efficient design, reducing maintenance requirements and enhancing overall reliability.

Frequently Asked Questions (FAQ) – Industrial Rotary Dryers in India

1. What is an Industrial rotary drier?

2. How does an Industrial Drum Dryer work?

3. What is a Steam Tube rotary drier?

4. Where can I buy the best Industrial rotary drier in India?

Important Keywords: Industrial Rotary Dryer System Provider in India, Industrial Drum Dryer System Provider In India, Steam Tube Rotary Dryer Supplier In India, Industrial Drum Dryer System Supplier In India, Industrial rotary drier Supplier for Chemical Industries, Industrial Rotary Dryer Supplier for Petrochemical Industries, Industrial Rotary Dryer Supplier for Mineral Industries

Related Searches:

Rotary Dryer Services Provider In India | Spray Dryer Services Provider In India | Agitated Thin Film Dryer Services Provider In India | Spin Flash Dryer Services Provider In India | Fluid Bed Dryer Services Provider In India | Industrial Dryer System Supplier In Provider | Industrial Drum Dryer System Provider in India | Steam Tube Rotary Dryer In India